Construction

Construction Process

The construction process of your new Sun Valley Pool starts with laying out the pool design in your backyard. This means transferring the drawn plans into your actual outdoor space to begin building the pool.

To make room for the pool, a backhoe is used to dig up the ground where the pool will be located. Once the hole is dug, the pool’s plumbing, steel bars for reinforcement, pool light fittings, and other necessary components are installed. This step prepares the pool for inspection by the city authorities.

Once the city inspector reviews the structure made of steel bars, they will give us the approval to order the concrete and pour it to create the pool shell.

Your chosen tile is then installed around the pool’s edges, creating a visually appealing perimeter. The pool decking, as specified in the pool plans, is formed and installed. Additional inspections are required before moving forward with the decking placement.

Finally, the inside of the pool is finished with your selected plaster material, giving your new Sun Valley Pool its unique touch. The pool is filled with water, and the filtration system is activated to start the cleaning and treatment process.

After the pool water has been properly treated, the pool is thoroughly cleaned, and all fixtures are installed, your new Sun Valley Pool is ready for you to enjoy for many years to come.

Shotcrete Pools

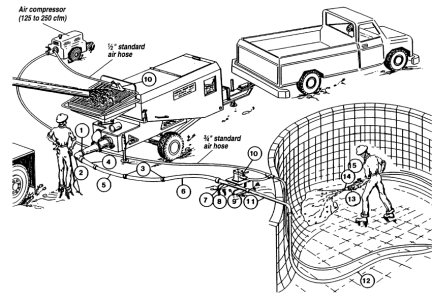

Shotcrete is a construction method commonly used for building swimming pools. It involves spraying a mixture of cement, sand, and water onto a steel framework or rebar structure at high velocity using a specialized pneumatic machine.

Shotcrete pools share similarities with gunite pools in terms of the materials used and the overall construction process. The main difference between the two lies in the application technique. While gunite involves mixing the dry materials on-site and adding water at the nozzle, shotcrete combines the pre-mixed wet mixture of cement, sand, and water and shoots it through the nozzle directly onto the pool’s structure.

Shotcrete pools offer several advantages. Like gunite, they provide excellent design flexibility and can be customized to fit various shapes, sizes, and features. The ability to shape and mold the pool during the construction process allows for creativity and unique designs that match the homeowner’s preferences.

One of the key benefits of shotcrete pools is their strength and durability. The high-velocity application of the wet mixture results in a dense and compact structure that provides exceptional structural integrity. Shotcrete pools have excellent resistance to cracking, shifting soil, and other potential sources of damage, making them a long-lasting choice for homeowners.

Shotcrete pools also offer a smooth and attractive surface finish. The application technique allows for a uniform texture that can be further enhanced with finishes like plaster, pebbles, or tiles. This smooth surface not only enhances the pool’s appearance but also provides a comfortable swimming experience.

Like gunite pools, shotcrete pools can accommodate a wide range of features and additions, allowing homeowners to incorporate waterfalls, spas, integrated seating, and other custom elements into their pool design.

It’s important to note that shotcrete pool construction requires specialized equipment and skilled professionals who have expertise in the shotcrete application process. Hiring an experienced pool builder with a track record of successfully constructing shotcrete pools is essential to ensure a high-quality and well-constructed pool.

In summary, shotcrete pools offer design flexibility, durability, and a smooth surface finish. They are a popular choice for homeowners looking to create a custom, long-lasting, and visually appealing swimming pool.